Services

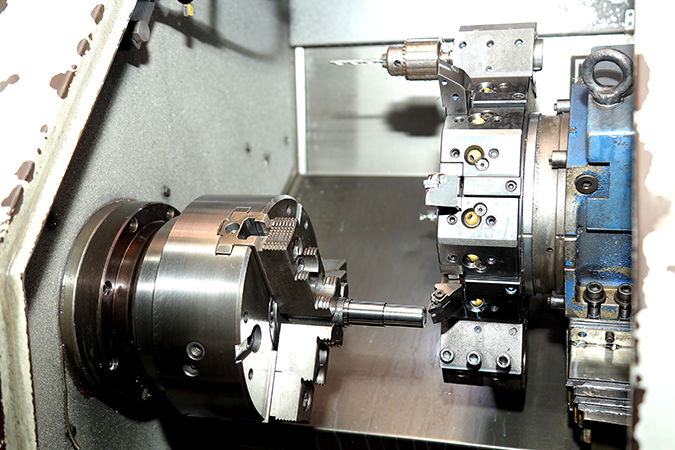

CNC TURNING CENTER

CNC Turning is a machining process used to make cylindrical parts, where the cutting tool moves in a linear fashion while the workpiece rotates. Commonly performed with a lathe, turning reduces the diameter of a workpiece, typically to a specified dimension, and produces a smooth part finish. A turning center is a lathe with a computer numerical control. Sophisticated turning centers can also perform a variety of milling and drilling operations. It is much efficient to deliver 150 workpiece per day.

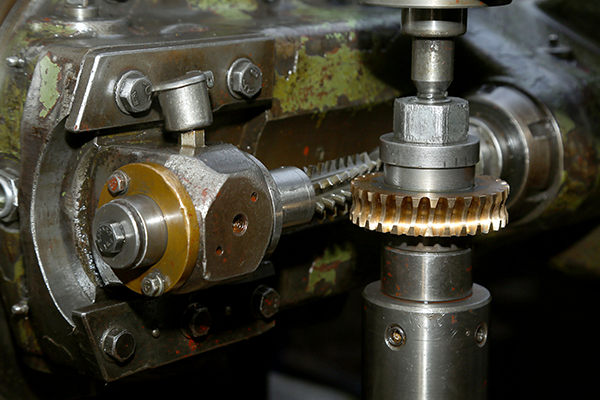

HOBBING MACHINE

A machine for cutting gear teeth in gear blanks or for cutting worm,spur, or helical gears. Also known as hobber.

The hob is a cutting tool used to cut the teeth into the workpiece. It is cylindrical in shape with helical cutting teeth. These teeth have grooves that run the length of the hob, which aid in cutting and chip removal. There are also special hobs designed for special gears such as the spline and sprocket gears.

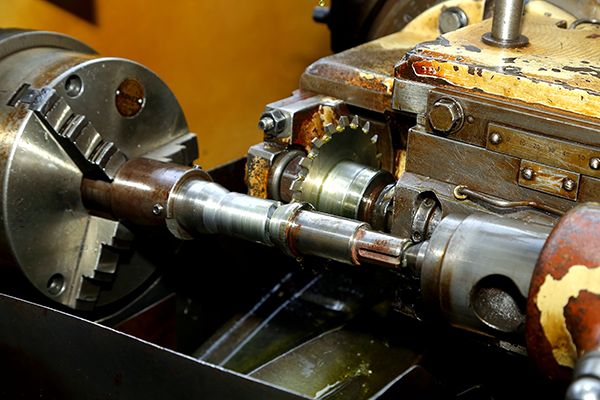

THREAD MILLING AND GRINDING MACHINE

Thread milling machine is used to make through out cut on shaft surface inform of number of teeth.

Same as grinding machine is used to smoothning sharp edges of workpiece after milling operation.

KEY WAY MACHINE FOR SHAFT

a key is a machine element used to connect a rotating machine element to a shaft. The key prevents relative rotation between the two parts and may enable torque transmission. For a key to function, the shaft and rotating machine element must have a keyway and a keyseat, which is a slot and pocket in which the key fits. The whole system is called a keyed joint.A keyed joint may allow relative axial movement between the parts. we have separate machine to make keyseat.

CENTER TESTING MACHINE

We have special machine to perform center testing of rotating component.